**Title: Diesel Generators for Condition Monitoring: Ensuring Reliability and Efficiency**

### Introduction

In an era where energy demands are ever-increasing, diesel generators have emerged as a critical component in various industries, providing reliable backup power and supporting primary energy needs. However, like any mechanical system, diesel generators are subject to wear and tear, which can lead to failures if not monitored properly. Condition monitoring has become an essential practice to enhance the reliability and efficiency of diesel generators, ensuring they perform optimally and reduce unplanned downtime. This article delves into the concept of condition monitoring for diesel generators, its importance, techniques, technologies, and best practices.

### Understanding Diesel Generators

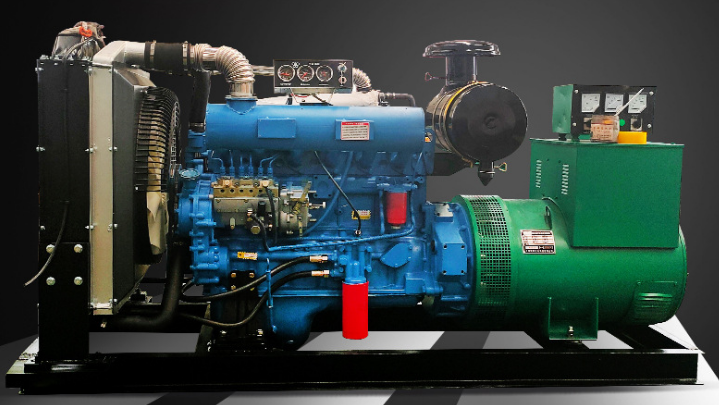

#### What is a Diesel Generator?

A diesel generator is a combination of a diesel engine and an electric generator (often referred to as an alternator) that converts mechanical energy produced by the engine into electrical energy. These generators are widely used in various applications, including:

- **Standby Power**: Providing backup electricity during outages.

- **Continuous Power**: Supplying power in remote locations without grid access.

- **Peak Shaving**: Reducing energy costs by providing additional power during peak demand times.

#### Components of a Diesel Generator

A typical diesel generator consists of several key components:

1. **Diesel Engine**: The heart of the generator that converts diesel fuel into mechanical energy.

2. **Alternator**: Converts mechanical energy into electrical energy.

3. **Control Panel**: Manages the operation, monitoring, and protection of the generator.

4. **Cooling System**: Maintains the engine's temperature within safe operating limits.

5. **Lubrication System**: Reduces friction and wear in engine components.

6. **Fuel System**: Supplies diesel fuel to the engine.

### Importance of Condition Monitoring

#### Preventing Failures

Condition monitoring plays a vital role in preventing unexpected failures of diesel generators. By continuously monitoring the health of the generator, potential issues can be identified and addressed before they result in costly downtime or equipment failure. Preventive maintenance helps in extending the lifespan of the generator.

#### Enhancing Performance

Regular condition monitoring ensures that diesel generators operate at peak efficiency. Monitoring key performance indicators (KPIs) such as fuel consumption, load handling, and emission levels enables operators to optimize performance and reduce operational costs.

#### Compliance and Safety

Many industries are subject to regulatory standards regarding emissions and safety. Condition monitoring can help ensure compliance with these regulations, reducing the risk of penalties and enhancing workplace safety by minimizing the risk of equipment failures.

#### Cost Savings

By implementing condition monitoring, organizations can reduce maintenance costs through better scheduling of maintenance activities. Early detection of issues can lead to less severe repairs, ultimately saving money on extensive repairs and downtime.

### Techniques for Condition Monitoring

Condition monitoring for diesel generators can be implemented through various techniques, each with its own advantages and applications. The following are some common techniques:

#### 1. Vibration Analysis

Vibration analysis involves measuring the vibrations produced by the diesel generator's components. Changes in vibration patterns can indicate issues such as misalignment, imbalance, or wear in rotating parts. By analyzing vibration data, technicians can identify potential problems early and schedule maintenance accordingly.

#### 2. Temperature Monitoring

Temperature monitoring of critical components, such as the engine, alternator, and exhaust system, is crucial for ensuring safe operation. Overheating can lead to severe damage and failure. Sensors can be installed to continuously monitor temperatures and alert operators when thresholds are exceeded.

#### 3. Oil Analysis

Regular oil analysis can provide insights into the health of the diesel engine. By examining oil samples for contaminants, wear particles, and chemical properties, operators can assess the condition of engine components and determine when oil changes are necessary.

#### 4. Fuel Quality Monitoring

The quality of diesel fuel is essential for optimal performance. Contaminants in fuel can lead to injector fouling, reduced combustion efficiency, and increased emissions. Monitoring fuel quality ensures that the engine operates smoothly and efficiently.

#### 5. Load Monitoring

Monitoring the load on the diesel generator helps ensure that it is operating within its rated capacity. Overloading can lead to overheating and premature wear, while underloading can result in inefficient fuel usage. Load monitoring helps maintain optimal performance.

### Technologies for Condition Monitoring

Advancements in technology have significantly enhanced condition monitoring capabilities for diesel generators. The following are some of the technologies commonly used:

#### 1. IoT and Remote Monitoring

The Internet of Things (IoT) allows for real-time monitoring of diesel generators from remote locations. 150kw diesel generator for remote transportation projects can collect data on various parameters, which is then transmitted to a central system for analysis. This technology enables operators to receive alerts and insights without being physically present at the generator site.

#### 2. Predictive Analytics

Predictive analytics involves using historical data and machine learning algorithms to predict future equipment failures. By analyzing trends and patterns, predictive maintenance strategies can be developed, allowing for proactive interventions before issues arise.

#### 3. Condition Monitoring Software

Dedicated condition monitoring software provides a comprehensive platform for collecting, analyzing, and visualizing data from diesel generators. These systems can integrate various monitoring techniques and provide dashboards for easy access to performance metrics and maintenance schedules.

#### 4. Cloud Computing

Cloud computing enables the storage and analysis of large amounts of data collected from diesel generators. This technology allows for advanced analytics, data sharing, and collaboration among maintenance teams, leading to better-informed decisions.

### Best Practices for Condition Monitoring

To maximize the benefits of condition monitoring for diesel generators, organizations should adopt the following best practices:

#### 1. Develop a Monitoring Strategy

A clear condition monitoring strategy should be developed, outlining the parameters to be monitored, the frequency of monitoring, and the responsibilities of personnel involved.

#### 2. Train Personnel

Proper training of maintenance personnel is essential for effective condition monitoring. Staff should be knowledgeable about the technologies used, data interpretation, and the maintenance procedures to be followed.

#### 3. Use Quality Equipment

Investing in high-quality sensors and monitoring equipment is crucial for obtaining accurate and reliable data. Low-quality equipment may lead to false readings and inadequate maintenance actions.

#### 4. Regular Data Review

Data collected from condition monitoring should be reviewed regularly to identify trends and potential issues. This review can help in adjusting maintenance schedules and responses based on the current condition of the generator.

#### 5. Engage in Continuous Improvement

Condition monitoring is not a one-time activity. Organizations should continuously seek to improve their monitoring processes, adopt new technologies, and refine their strategies based on lessons learned and industry best practices.

### Conclusion

Diesel generators play an indispensable role in ensuring reliable power supply across various sectors. However, to keep these vital systems running efficiently and reliably, condition monitoring is essential. By adopting effective monitoring techniques and leveraging modern technologies, organizations can enhance the performance of diesel generators, prevent costly failures, and ensure compliance with safety and regulatory standards.

As the energy landscape continues to evolve, integrating robust condition monitoring practices will not only safeguard investments in diesel generators but also contribute to a more sustainable and efficient future in energy management. Embracing this proactive approach will empower organizations to harness the full potential of their diesel generator systems, ensuring they remain a dependable source of power for years to come.

---

This article serves as a comprehensive guide to understanding the significance of condition monitoring for diesel generators, covering its importance, techniques, technologies, and best practices to help organizations optimize their operations.